Concurrent Engineering Definition

The definition of Concurrent Engineering that we have adopted for the Concurrent Design Facility is: 'Concurrent Engineering (CE) is a systematic approach to integrated product development that emphasises the response to customer expectations.

She's watched it since she was about 6 months old! My daughter is 22 months old and LOVES Mickey Mouse Clubhouse. When I seen this movie came out, I was at the store the day it was released. I have every movie and all the shows on Disney on our DVR player.

She's watched it since she was about 6 months old! My daughter is 22 months old and LOVES Mickey Mouse Clubhouse. When I seen this movie came out, I was at the store the day it was released. I have every movie and all the shows on Disney on our DVR player.

Training is for the tools used in CE, usually computer aided drafting. Another important yet overlooked training is in non-technical areas, such as problem-solving and conflict resolution.

Concurrent engineering (CE) is a work methodology emphasizing the parallelisation of tasks (i.e. performing tasks concurrently), which is sometimes called simultaneous engineering or integrated product development (IPD) using an integrated product team approach. It refers to an approach used in product development in which functions of design engineering, manufacturing engineering, and other functions are integrated to reduce the time required to bring a new product to market.[1]

- 1Introduction

- 2Elements

Introduction[edit]

A 2008 publication described concurrent engineering as a new design management system that has matured in recent years to become a well-defined systems approach to optimizing design and engineering cycles.[2] Concurrent engineering has been implemented in a number of companies, organizations, and universities, most notably in the aerospace industry. Beginning in the early 1990s, CE was also adapted for use in the information and content automation field, providing a basis for organization and management of projects outside the physical product development sector for which it was originally designed. Organizations such as the European Space Agency's Concurrent Design Facility make use of concurrent design to perform feasibility studies for future missions.

The basic premise for concurrent engineering revolves around two concepts. The first is the idea that all elements of a product's life-cycle—from functionality, production, assembly, testing, maintenance, environmental impact, and finally disposal and recycling—should be taken into careful consideration in the early design phases.[3]

Social Engineering Definition Security

The second concept is that design activities should all be occurring at the same time, i.e., concurrently. The idea is that the concurrent nature of these activities significantly increases productivity and product quality.[4] This way, errors and redesigns can be discovered early in the design process when the project is still flexible. By locating and fixing these issues early, the design team can avoid what often become costly errors as the project moves to more complicated computational models and eventually into the actual manufacturing of hardware.[5]

As mentioned above, part of the design process is to ensure that the product's entire life cycle is taken into consideration. This includes establishing user requirements, propagating early conceptual designs, running computational models, creating physical prototypes, and eventually manufacturing the product. Included in this process is taking into full account funding, workforce capability, and time requirements. A 2006 study claimed that a correct implementation of the concurrent design process can save a significant amount of money, and that organizations have been moving to concurrent design for this reason.[4] It is also highly compatible with systems thinking and green engineering.

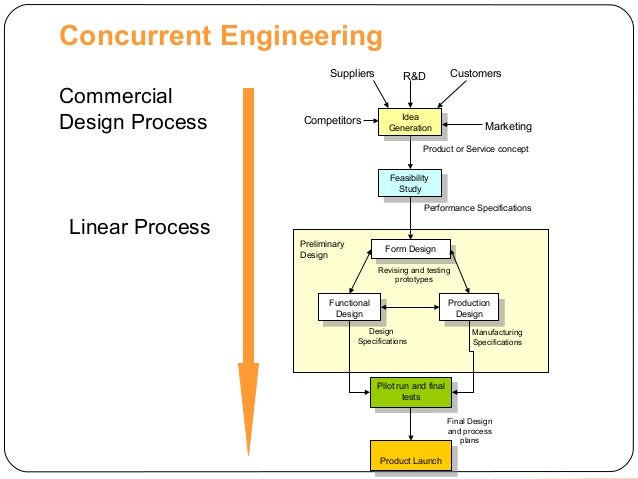

Concurrent engineering replaces the more traditional sequential design flow, or 'Waterfall Model'.[6][7] In Concurrent Engineering an iterative or integrated development method is used instead.[8] The Waterfall method moves in a linear fashion, starting with user requirements and sequentially moving forward to design and implementation, until you have a finished product. In this design system, a design team would not quickly look backward or forward from the step it is on to fix or anticipate problems. In the case that something does go wrong, the design usually must be scrapped or heavily altered. The concurrent or iterative design process encourages prompt changes of tack, so that all aspects of the life cycle of the product are taken into account, allowing for a more evolutionary approach to design.[9] The difference between the two design processes can be seen graphically in Figure 1.

A significant part of the concurrent design method is that the individual engineer is given much more say in the overall design process due to the collaborative nature of concurrent engineering. Giving the designer ownership is claimed to improve the productivity of the employee and quality of the product, based on the assumption that people who are given a sense of gratification and ownership over their work tend to work harder and design a more robust product, as opposed to an employee that is assigned a task with little say in the general process.[5]

Challenges associated with concurrent design[edit]

Concurrent design comes with a series of challenges, such as implementation of early design reviews, dependency on efficient communication between engineers and teams, software compatibility, and opening up the design process.[10] This design process usually requires that computer models (computer aided design, finite element analysis) are exchanged efficiently, something that can be difficult in practice. If such issues are not addressed properly, concurrent design may not work effectively.[11] It is important to note that although the nature of some project activities project imposes a degree of linearity—completion of software code, prototype development and testing, for example—organizing and managing project teams to facilitate concurrent design can still yield significant benefits that come from the improved sharing of information.

Service providers exist that specialize in this field, not only training people how to perform concurrent design effectively, but also providing the tools to enhance the communication between the team members.

Elements[edit]

Cross-functional teams[edit]

Cross-functional teams include people from different area of the workplace that are all involved in a particular process, including manufacturing, hardware and software design, marketing, and so forth.

Concurrent product realization[edit]

Doing several things at once, such as designing various subsystems simultaneously, is critical to reducing design time and is at the heart of concurrent engineering.

Incremental information sharing[edit]

Incremental information sharing helps minimize the chance that concurrent product realization will lead to surprises. 'Incremental' meaning that as soon as new information becomes available, it is shared and integrated into the design. Cross-functional teams are important to the effective sharing of information in a timely fashion.

Integrated project management[edit]

Integrated project management ensures that someone is responsible for the entire project, and that responsibility is not abdicated once one aspect of the work is done.

Definition[edit]

Several definitions of concurrent engineering are in use.

The first one is used by the Concurrent Design Facility (ESA):

| “ | Concurrent Engineering (CE) is a systematic approach to integrated product development that emphasizes the response to customer expectations. It embodies team values of co-operation, trust and sharing in such a manner that decision making is by consensus, involving all perspectives in parallel, from the beginning of the product life cycle. | ” |

The second one is by Winner, et al., 1988:

| “ | Concurrent Engineering is a systematic approach to the integrated, concurrent design of products and their related processes, including, manufacturing and support. This approach is intended to cause the developers from the very outset to consider all elements of the product life cycle, from conception to disposal, including quality, cost, schedule, and user requirements.[12] | ” |

Using C.E.[edit]

Currently, several companies, agencies and universities use CE. Among them can be mentioned:

- European Space AgencyConcurrent Design Facility

- NASATeam X - Jet Propulsion Laboratory

- NASAIntegrated Design Center (IDC), Mission Design Lab (MDL), and Instrument Design Lab (IDL) - Goddard Space Flight Center

- CNES – French Space Agency

- ASI – Italian Space Agency

- Boeing

- EADS Astrium – Satellite Design Office

- The Aerospace Corporation Concept Design Center

See also[edit]

- ESA's Concurrent Design Facility

References[edit]

- ^'The Principles of Integrated Product Development'. NPD Solutions. DRM Associates. 2016. Retrieved 7 May 2017.

- ^Ma, Y., Chen, G. & Thimm, G.; 'Paradigm Shift: Unified and Associative Feature-based Concurrent Engineering and Collaborative Engineering', Journal of Intelligent Manufacturing, DOI 10.1007/s10845-008-0128-y

- ^Kusiak, Andrew; Concurrent Engineering: Automation, Tools and Techniques

- ^ abQuan, W. & Jianmin, H., A Study on Collaborative Mechanism for Product Design in Distributed Concurrent Engineering IEEE 2006. DOI: 10.1109/CAIDCD.2006.329445

- ^ abKusiak, Andrew, Concurrent Engineering: Automation, Tools and Techniques

- ^'The standard waterfall model for systems development', NASA Webpage, November 14, 2008

- ^Kock, N. and Nosek, J., 'Expanding the Boundaries of E-Collaboration', IEEE Transactions on Professional Communication, Vol 48 No 1, March 2005.

- ^Ma, Y., Chen, G., Thimm, G., 'Paradigm Shift: Unified and Associative Feature-based Concurrent Engineering and Collaborative Engineering', Journal of Intelligent Manufacturing, DOI 10.1007/s10845-008-0128-y

- ^Royce, Winston, 'Managing the Development of Large Software Systems', Proceedings of IEEE WESCON 26 (August 1970): 1-9.

- ^Kusiak, Andrew, 'Concurrent Engineering: Automation, Tools and Techniques'

- ^Rosenblatt, A. and Watson, G. (1991). 'Concurrent Engineering', IEEE Spectrum, July, pp 22-37.

- ^Winner, Robert I., Pennell, James P., Bertrand, Harold E., and Slusarczuk, Marko M. G. (1991). 'The Role of Concurrent Engineering in Weapons System Acquisition', Institute for Defense Analyses Report R-338, December 1988, p v.